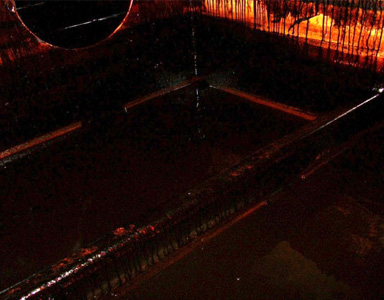

Baymarine were asked to clean and recoat the Adonia’s ballast tanks in service after the tank became contaminated with HFO (heavy fuel oil) due to a burst pipe. The coating in the tank was also in need of repair and was contributing to the problem.

For this project, our experts decided that the Chemco RS500P system was the right choice. Baymarine and Chemco have completed many projects together over the years, both at service and at port worldwide.

It is solvent free, odourless, and can cure underwater, thus bringing the tank back in service causing little disruption to the passengers and crew alike, saving costly dockings or layups. The results speak for themselves!

OUR SOLUTION

We sprayed the tank with grease master and freshwater washed to remove the oil residue deep into steel substrates, then we high pressure blasted at 500 bar (8000psi) to W J 3 standard.For this project, our experts decided that the Chemco RS500P system was the right choice. Baymarine and Chemco have completed many projects together over the years, both at service and at port worldwide.

It is solvent free, odourless, and can cure underwater, thus bringing the tank back in service causing little disruption to the passengers and crew alike, saving costly dockings or layups. The results speak for themselves!